Turkey, located at the junction of Eurasia, plays an important role in the world ceramic industry. According to the Ceramic World Web, in 2021, the Turkish ceramic tile production reached 438 million square metres, the domestic sales were 291 million square metres, and the exports were 154 million square metres, all of which were leading in the world.

Since 2015, Turkey's ceramic factories have changed, especially in the last three years. For example, large production lines have started to be built. These new production lines have daily production capacity exceeding 10,000 square metres.

The new equipment and production process have a significant impact on the factory. These new production lines have significantly increased production and reduced energy consumption.Overall, under the same quality conditions, the production cost per square meter of ceramic tiles can be reduced by at least 20%. At the same time, these factories can participate in market competition at more cost-effective prices.

According to Ceramic Town Weekly, in 2023, by the end of May, the kiln firing schedule of Turkey's ceramic industry was less than half (about 40%). Domestic ceramic manufacturers are facing changes and adjustments.

Turkey's ceramic industry ushers Chinese Manufacturing Model

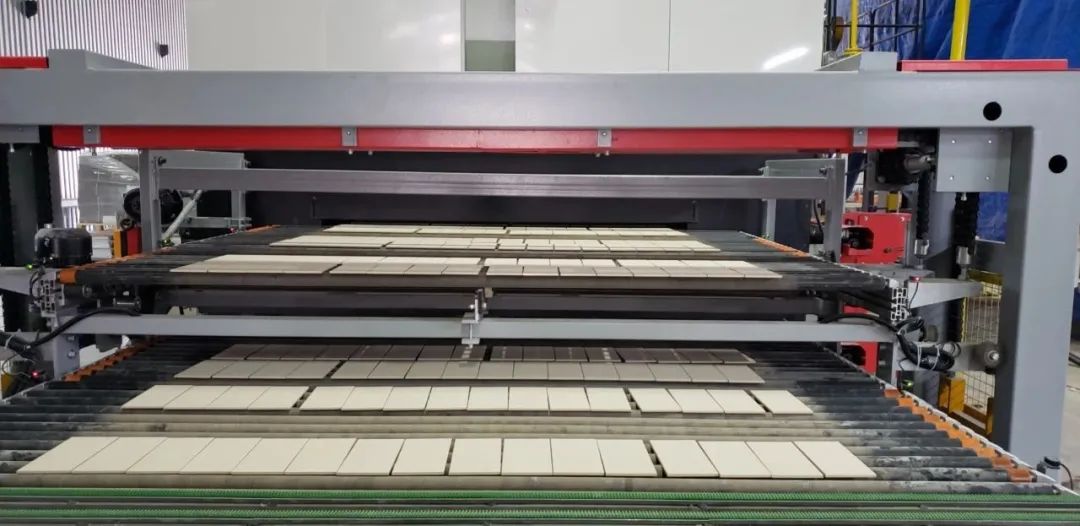

A line production up to 35,000 sqm. per day

At present, there are 25 ceramic enterprises in Turkey. In the past, these ceramic manufacturers usually used equipment provided by European ceramic machinery enterprises to build production lines, which were characterized by small production capacity (daily production capacity of 5,000-8,000 sqm. ) and flexibility (many compensators and AGVs were installed before and after the kiln).

However, since 2015, some production lines provided by Chinese machinery enterprises have appeared in Turkish ceramic factories. These production lines usually have the characteristics of "small investment, large output". The biggest difference from traditional models is that the daily output exceeds 10,000 square meters, and the kiln is directly connected to the polishing process, without the need for many compensators and AGVs. Continuous production is also known as the "Chinese Manufacturing Model".

In 2018, one of the manufacturers put into operation a production line constructed by Chinese machinery enterprise KEDA. The project included continuous ball mill, press, dryer, kiln, and polishing line, which were provided by KEDA, with a daily production capacity of 12,000 sqm. and a main production was glazed tiles with specification of 60 × 60 cm and 60 × 120 cm.

This production line achieved great success after being put into operation, which becomes the line with the best return on investment. Before then, they have already invested a kiln provided by KEDA and achieved success as well. Based on successful experience of cooperation, they will chose KEDA as the equipment supplier for their subsequent expansion plan.

Recently, more and more manufacturers are investing large output production line. According to relevant sources, 95% of the new or revamped Turkish production lines in recent years have used Chinese polishing equipment. In addition, more than 70 Chinese presses have been selected.

It is worth sharing that the maximum production line in the local area has reached 35,000 sqm. per day.

Why is the large output model popular?

Why do Turkish ceramic enterprises begin to change their manufacturing model? On the one hand, it is the market competition, on the other hand, it is the improvement of equipment and technology.

It is reported that Chinese ceramic machinery enterprises have actively improved their equipment in response to the needs of the Turkish market, including automation, environmental protection and energy conservation. Some Chinese ceramic machinery enterprises have customized their equipment specifically for the Turkish market. From 2005 to 2015, in order to make a breakthrough in the Turkish market, Chinese enterprises changed the views of local enterprises with considerate services, which received favorable reviews.

By 2015, some Turkish forward-looking and adventurous ceramic entrepreneurs tried to cooperate with Chinese ceramic machinery enterprises to build production lines. The success of several "low investment, high return" projects has quickly become well-known in the local area, giving more people confidence to use Chinese Products and Manufacturing Model.

Another reason why Chinese ceramic machinery enterprises are respected by Turkish enterprises is after-sales service and maintenance. In order to eliminate the worries of customers in Turkey and provide better customer services, KEDA has not only set up a Turkish subsidiary to provide local storage, sales and maintenance services for spare parts and consumables. At the same time, local employees have been recruited to build a localized service system.

In the past two years, with the increase of energy prices and the intensification of market competition, Turkey's ceramic industry was facing difficulties. Local ceramic enterprises are actively seeking solutions to address challenges, including producing differentiated products and improving the competitiveness of factories.

In any case, Turkey's ceramic industry is experiencing changes. The old production lines need to be technically reformed or renovated to ensure that they still have competitive advantages compared with their peers. This is also an issue that ceramic companies around the world need to face with.

If you are interested in the high output manufacturing model, please follow and subscribe our Ceramic Town Weekly account. We will release more relevant reports and conduct more detailed analysis on this topic.

(Edited by CTW陶城报)